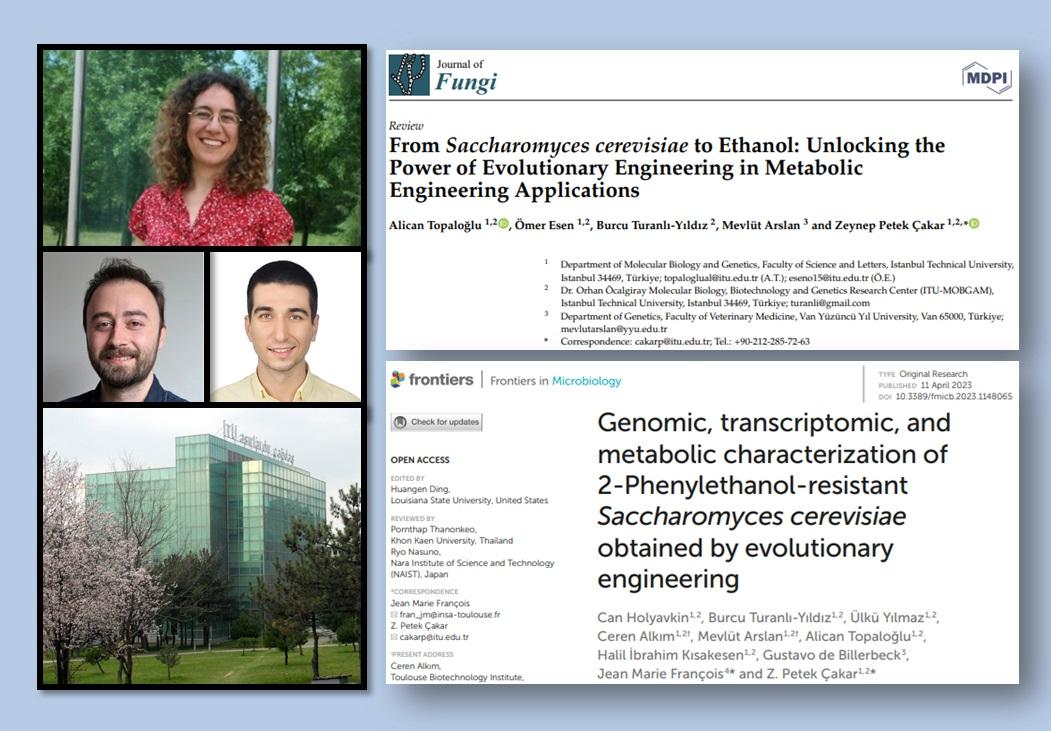

Prof. Dr. Zeynep Petek Çakar's research group at ITU Department of Molecular Biology & Genetics has been successfully improving resistance of yeast cells to various industrial stress types. For this purpose, the research group has been employing the highly effective inverse metabolic engineering approach known as adaptive laboratory evolution or evolutionary engineering. The stress responses and resistance exhibited by yeast cells during the evolutionary engineering process alter their typical physiological behavior. It is imperative to identify the metabolic and molecular differences between the original and evolved yeast cells to develop microorganisms that exhibit improved characteristics relevant to industrial applications.

In their recent invited review article published in the special issue ‘Yeast Metabolic Engineering for Bio-Based Fuels, Chemicals and Materials’ of the Journal of Fungi (a Q1 journal according to Scopus index), they provide a comprehensive overview of metabolic and evolutionary engineering studies for improved first- and second-generation yeast (S. cerevisiae) bioethanol production processes. The authors delve into the current state of the field and show that metabolic and evolutionary engineering strategies are intertwined and many metabolically engineered strains for bioethanol production can be further improved by powerful evolutionary engineering strategies. They also discuss potential future directions that involve recent advancements in directed genome evolution, including CRISPR-Cas9 technology.

A recent research of the group also focused on improving the production of the valuable flavor compound, 2-phenylethanol, by increasing resistance of yeast cells to product inhibition. In that article published in Frontiers in Microbiology (a Q1 journal according to Scopus index ), Prof. Çakar’s group and her collaborators (the research group of Prof. Dr. Jean Marie François, Toulouse Biotechnology Institute, University of Toulouse, France) developed a 2-phenylethanol-resistant S. cerevisiae strain by evolutionary engineering and characterized the evolved strain at the genomic, transcriptomic and metabolic levels. The evolved S. cerevisiae strain had three-fold improved tolerance to 2-phenylethanol, and it acquired a physiological state described as the environmental stress response (ESR). This stressful state of the evolved strain may be associated with a mutation found in its HOG1 gene leading to a hyperactive MAPKinase, activating the Msn2/4p transcription factor. Additionally, the transcriptional activation of ALD3 gene encoding a NAD+ -dependent aldehyde dehydrogenase that is responsible for the oxidation of 2-phenylacetaldehyde into the less toxic 2-phenylacetate may be the mechanism for reducing the 2-phenylethanol toxicity in yeast.

For further information:

Topaloğlu A, Esen Ö, Turanlı-Yıldız B, Arslan M and Çakar ZP. (2023) From Saccharomyces cerevisiae to Ethanol: Unlocking the Power of Evolutionary Engineering in Metabolic Engineering Applications. J Fungi. 9(10):984. doi: 10.3390/jof9100984.

Holyavkin C, Turanlı-Yıldız B, Yılmaz Ü, Alkım C, Arslan M, Topaloğlu A, Kısakesen Hİ, de Billerbeck G, François JM and Çakar ZP (2023). Genomic, transcriptomic, and metabolic characterization of 2-Phenylethanol-resistant Saccharomyces cerevisiae obtained by evolutionary engineering. Front. Microbiol. 14:1148065. doi: 10.3389/fmicb.2023.1148065

https://www.mdpi.com/2309-608X/9/10/984

https://www.frontiersin.org/articles/10.3389/fmicb.2023.1148065/full